Spray Nozzle FOR CCM

Spray nozzle is a key component in continuous casting process, mainly used to spray cooling medium to the surface of billet to control the cooling rate and temperature distribution of billet. It has an important influence on the quality, internal organization and production efficiency of the billet in the continuous casting process.

1.Main functions

Control cooling rate: control the cooling rate of billet by adjusting the flow and pressure of cooling medium.

Uniform cooling: Ensure uniform temperature distribution on the surface and inside of the billet to avoid cracks and deformation.

Improve the quality of billet: optimize the internal organization of billet and improve its mechanical properties.

Extend the life of equipment: reduce the damage of high temperature to continuous casting equipment through effective cooling.

2.Working principle

The cooling medium (water or aerosol) is transported to the nozzle through the pipeline.

The cooling medium is sprayed out from the injection holes and evenly covers the surface of the casting billet.

The cooling rate and temperature distribution of the billet is controlled by adjusting the flow rate and pressure.

The cooled billet goes to the next process (e.g. drawing, cutting, etc.).

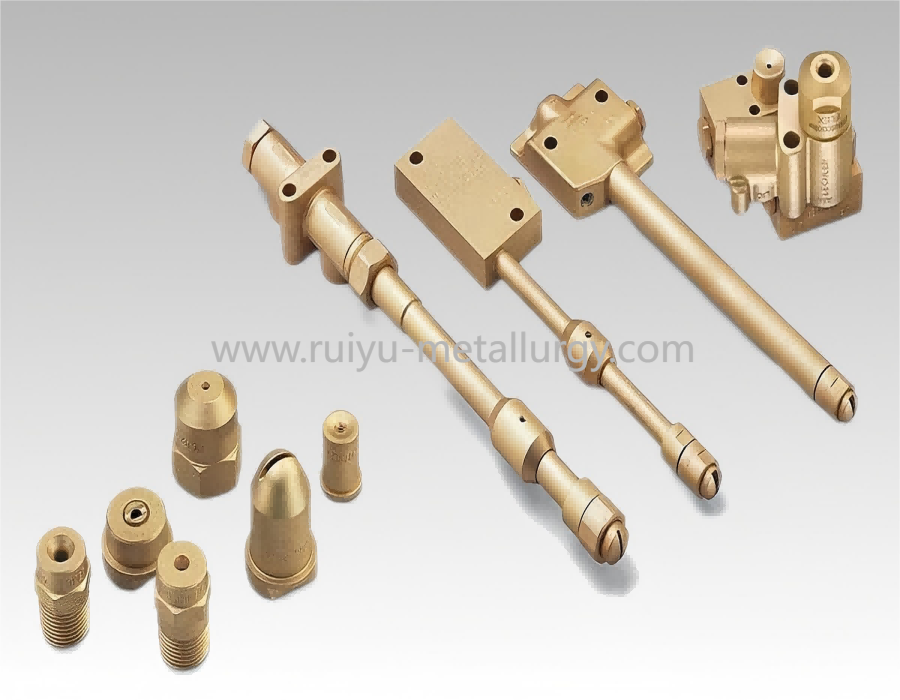

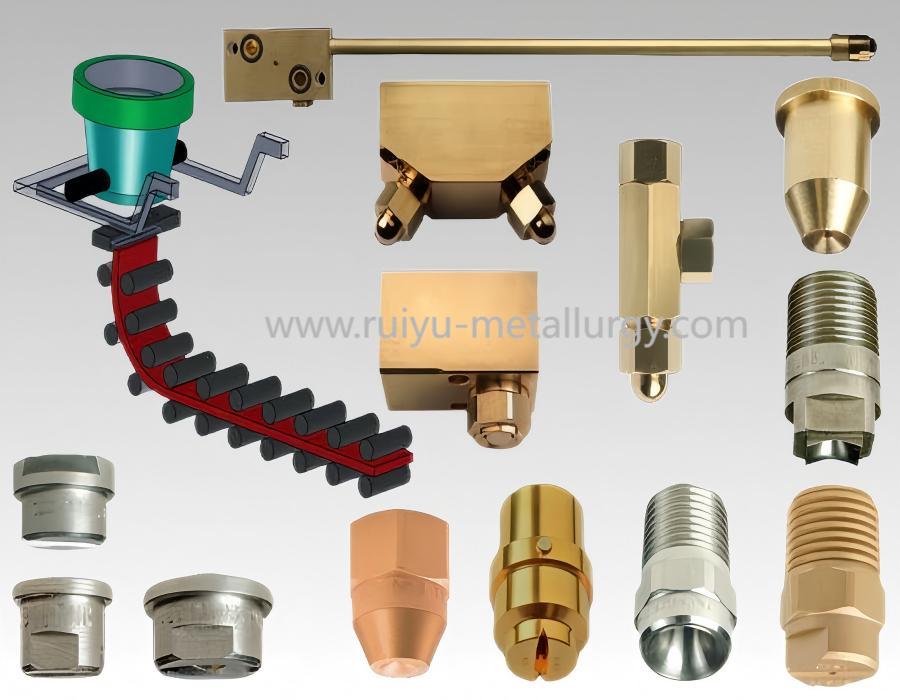

3.Types

According to the installation position, continuous casting nozzle can be divided into:

Copper mold nozzle: installed in the Copper mold area, for the initial cooling.

Second cooling zone nozzle: installed in the second cooling zone, used for secondary cooling.

Auxiliary nozzles: used for special cooling needs, such as edge cooling.

4.Precautions

Nozzle selection: Select the appropriate nozzle type and specification according to the type of billet and cooling requirements.

Regular maintenance: Regularly check the injection holes of the nozzles to prevent clogging and wear.

Parameter adjustment: According to the temperature and cooling requirements of the billet, reasonably adjust the flow rate and pressure of the cooling medium.

Water quality management: Ensure the cleanliness of cooling water to prevent nozzle clogging and equipment corrosion.

Our company has many years of experience in the production and marketing of spray nozzles for CCM, with professional technical personnel, according to the individual needs of customers, production and processing. The above parameter data can be used for reference, if you have specific needs, please feel free to contact us.