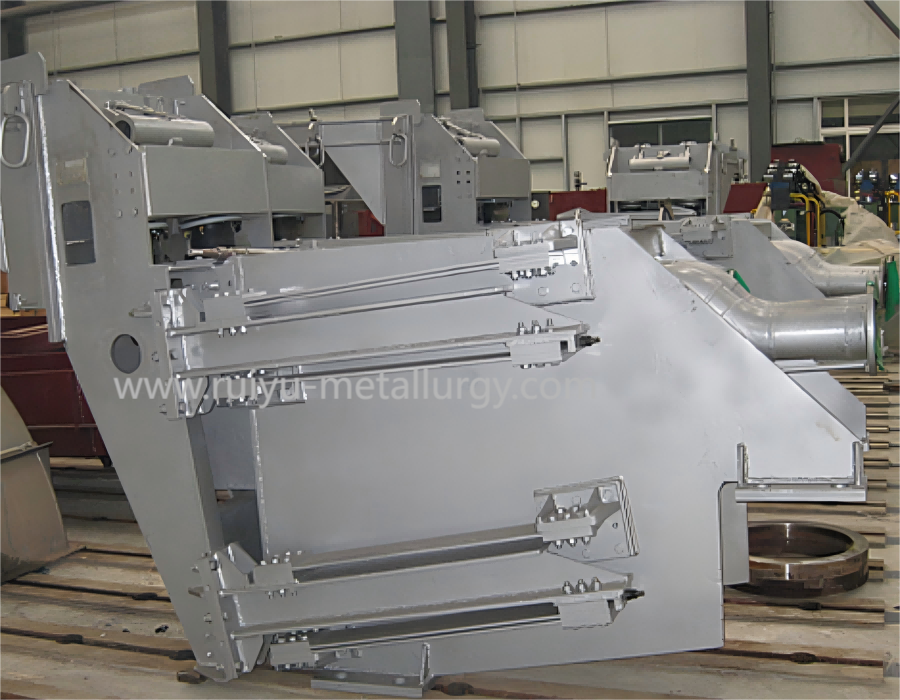

Mould Oscillato

Mould oscillator for continuous casting machine is one of the crucial equipments in the continuous steel casting process, its main function is to help the separation of copper mold and casting billet by means of vibration, so as to ensure the quality of casting billet and production efficiency. In recent years, with the continuous progress of technology, the design and application of mould oscillato has been optimized.

Role of mold oscillator

- Control billet structure

Through the vibration of continuous casting vibrating table, can improve the grain structure in the cast billet, so as to control the structure of the cast billet, reduce section cracks, transverse cracks, segregation and other defects, improve the quality of the cast billet.

- Improve the quality of billet

Continuous casting vibrating table vibration can also promote the casting of inclusions, bubbles and other non-metallic inclusions in the billet floating and dispersion, so as to reduce or eliminate the casting surface, internal defects, to improve the quality of the casting.

- Improve production efficiency

After the shaking table treatment, the surface finish of the cast billet is improved, the surface quality is improved, which can reduce the probability of quality problems occurring in the cast billet de-surface, so as to improve the production efficiency.

Main parameters:

| Structure type | Full leaf spring, half leaf spring, four connecting rod | |

| Drive type | Traditional mechanical drive | |

| Hydraulic cylinder,electric cylinder drive | ||

| Servo motor drive | ||

| Vibration curve | Traditional mechanical drive | Sine curve |

| Hydraulic cylinder,electric cylinder drive | Sinusoidal or non-sinusoidal | |

| Servo motor drive | Sinusoidal or non-sinusoidal | |

| Vibration frequency | 0~300 times/min (hydraulic, electric cylinder and servo motor drive can be adjusted online) | |

| amplitude | 0~10mm (hydraulic, electric cylinder and servo motor drive can be adjusted online) | |

Our company has many years of experience in the production and marketing of mold oscillators, with professional technical personnel, according to the individual needs of customers, production and processing. The above parameter data can be used for reference, if you have specific needs, please feel free to contact us.