Copper plates are used in the continuous casting process to guide the solidification of liquid metal (e.g. molten steel) into a specific shape, usually in the form of a flat or shaped plate structure. Its core functions include:

Rapid thermal conductivity: Through the high thermal conductivity of copper (380~400 W/(m-K)), the heat of molten steel is quickly absorbed to form a uniform solid billet shell.

Precise shape control: Compensate solidification shrinkage through the geometry of the copper plate (e.g. taper, curved surface) to reduce cracks and deformation of the cast billet.

Wear-resistant and corrosion-resistant: Surface plating protects the copper substrate against steel washout and high-temperature oxidation.

- Basic structure

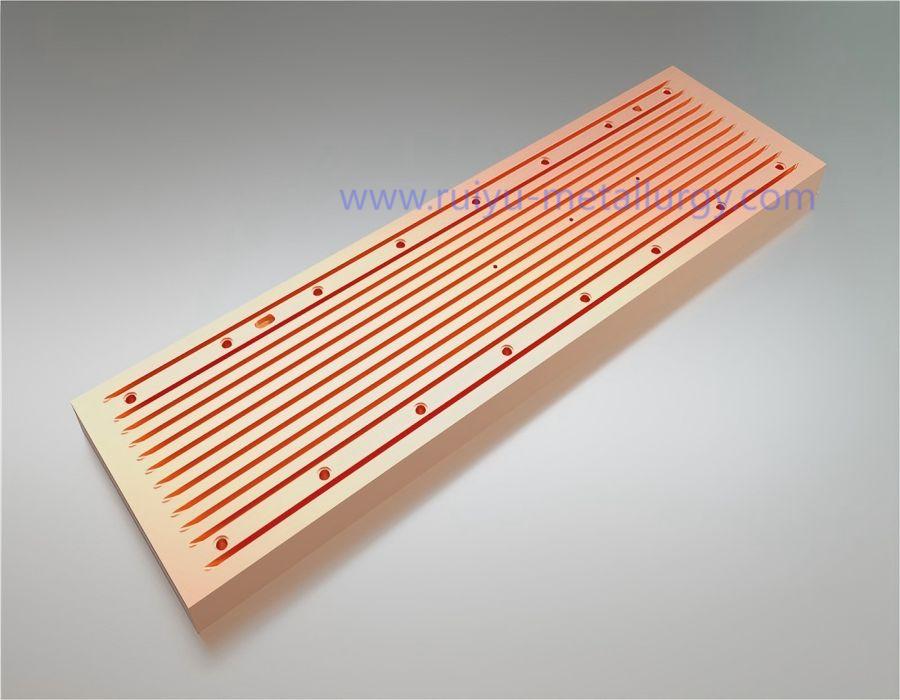

Working surface: the surface in direct contact with molten steel, requiring high-precision machining (roughness Ra ≤ 0.8μm) and coated with wear-resistant layer (e.g. chrome plating).

Cooling layer: Dense cooling channels or grooves are designed on the back side to dissipate heat quickly by high pressure water flow (1.0~1.5MPa).

Mounting interface: bolt holes or grooves for connection with the crystallizer frame to ensure stable fixing of the copper plate.

2、Special structure type

Combined copper plate: block splicing design, easy for local replacement (e.g. wide-face copper plate for slab continuous casting).

Shaped copper plate: used in the production of H-type steel, rail steel and other complex sections of billet casting, the shape of the inner cavity needs to be matched with the finished product.

Thin strip copper plate: used for thin strip continuous casting (thickness <10mm), the working surface needs to be polished with ultra-high precision (Ra≤0.4μm).

- Material type

High-conductivity oxygen-free copper Cu ≥ 99.95%, thermal conductivity ≥ 380 W/(m-K), suitable for low-drawing speed, small-section billet casting

Chromium-zirconium copper alloy Cu-Cr(0.6%~1.2%)-Zr(0.03%~0.3%), tensile strength ≥350MPa for high pulling speed, large cross-section slabs

Silver-copper alloy Cu-Ag (0.08% ~ 0.12%), high-temperature strength increase of 20%, suitable for high-temperature steel (such as stainless steel) continuous casting

- Surface plating

Chrome plating: hardness 800~1000HV, temperature resistance ≤500℃, low cost but poor thermal fatigue resistance.

Nickel-cobalt alloy plating (Ni-Co): hardness 500 ~ 600HV, high toughness, excellent resistance to thermal cracking performance.

Composite plating: bottom layer nickel plating (0.1mm) + surface layer chromium plating (0.05mm), taking into account wear resistance and thermal shock resistance.

- Typical applications

Continuous casting of slabs: the length of wide copper plate can be up to 2000mm, producing slabs with thickness of 150~300mm.

Shaped billet continuous casting: such as I-beam, channel steel, etc., the shape of the inner cavity of the copper plate needs to be exactly the same as the section of the cast billet.

Thin strip continuous casting: copper plate working surface needs to be super straight (≤0.05mm/m), cooling strength requirements are extremely high.

6、Common Problems.

Plating flaking: mostly due to excessive thermal stress or insufficient plating bonding, need to optimize the plating process (e.g. sand blasting and roughening before plating).

Uneven cooling: mostly due to scale clogging or poorly designed waterways, regular pickling of waterways and optimization of waterway distribution are needed.

Deformation of working surface: mostly caused by long term high temperature creep or mechanical impact, need to use chrome zirconium copper material, control the drawing speed and temperature.

Cracks on the surface of billet: mostly caused by mismatch of taper of copper plate or too strong cooling, need to adjust the taper curve and reduce the local cooling intensity.

7.Reference parameters

Thickness: 40~100mm (working surface + cooling layer)

Plating thickness: chromium plating 0.05~0.2mm; nickel-based alloy 0.1~0.3mm

Cooling waterway: Slot depth 5~10mm, spacing 15~30mm

Taper design: unilateral taper 0.5%~2.0

Our company has rich experience in the production and marketing of crystallizer copper plate, with professional technical personnel, according to the individual needs of customers, production and processing.

The above parameter data can be used for reference, if you have specific needs, please feel free to contact us.